The satisfaction of all the employees and workers on the site is extremely important for overall success. Hence, ensuring their safety and good working condition from time to time is needed in all the manufacturing sites.

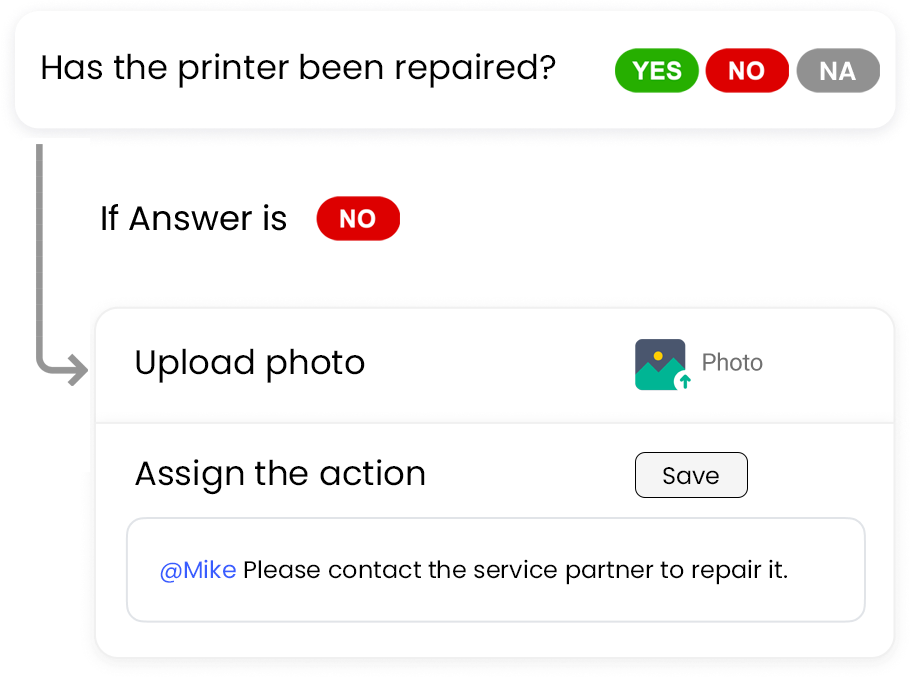

Pulse allows you to edit the checklists from the library to suit your specific needs. With our smart checklist builder and editor, you can infuse logic in your questions for more clarity and better visibility.

SIGN UP TO EDIT TEMPLATES

Pulse helps you convert your existing inspection templates into digital ones. Simply upload them in PDF, Excel and Word format and leave the rest for our support team. We will get back to you with digital forms.