The instruments at the site are the heart of the business. For each machine, depending on the application and end goal, torque requirements can differ. Thus, torque wrenches are commonly used at manufacturing sites. However, a fault in the torque wrench can give results opposite to the required specifications, thus, a frequent audit is required to inspect the calibration process. Such an inspection also ensures that a calibration process is always done under certain guidelines.

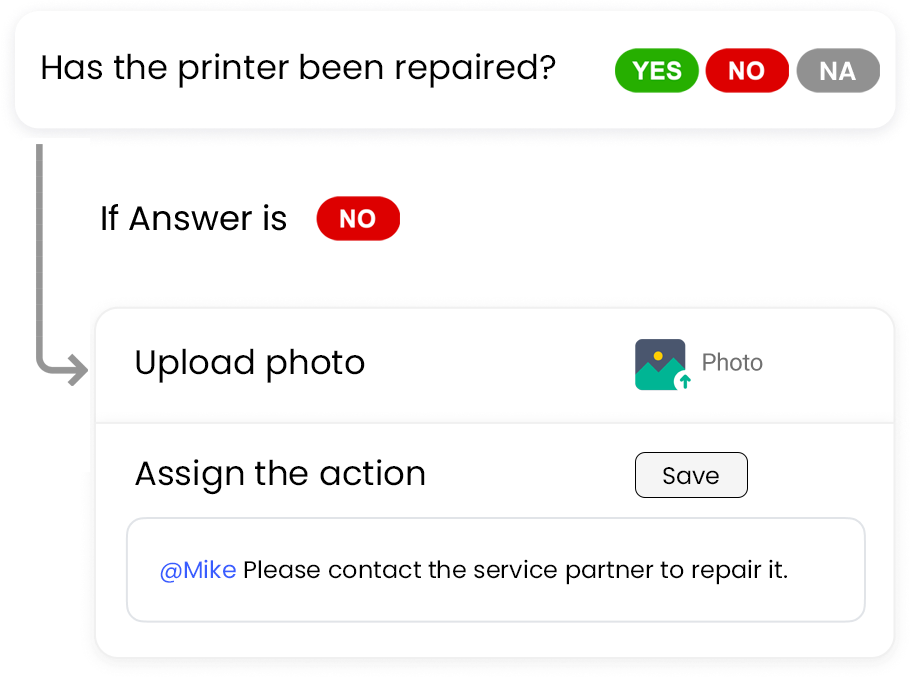

Pulse allows you to edit the checklists from the library to suit your specific needs. With our smart checklist builder and editor, you can infuse logic in your questions for more clarity and better visibility.

SIGN UP TO EDIT TEMPLATES

Pulse helps you convert your existing inspection templates into digital ones. Simply upload them in PDF, Excel and Word format and leave the rest for our support team. We will get back to you with digital forms.